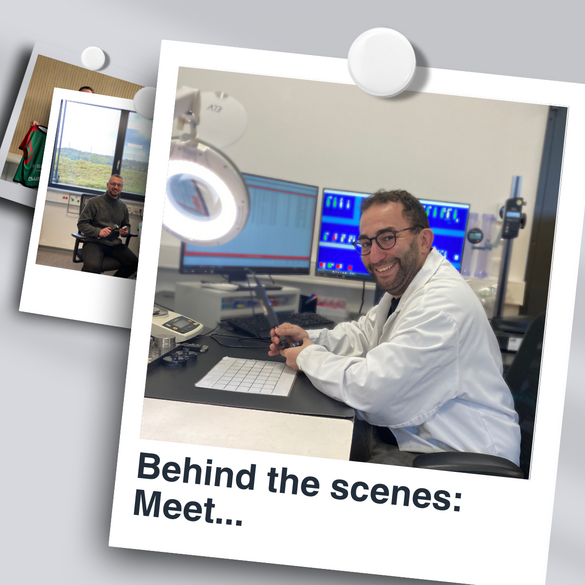

Emre joined SABEU in January 2020, starting in production before becoming a key member of our Quality Assurance team. With a trained eye for detail, he ensures every product meets our high standards — working with precision and full focus in a three-shift system.

From production to quality assurance

Before joining SABEU, Emre worked as a warehouse specialist. Looking for new challenges and growth opportunities, he moved into production — manufacturing housings and operating automated machines for small parts. His curiosity and drive led him to Quality Assurance, where since September 2023 he’s been inspecting plastic parts across all business areas.

“I check that everything fits as it should. If not, the machine has to stop — quality always comes first.”

Precision down to the smallest detail

From housings and screw caps to medical technology components, Emre checks measurements, surfaces, and visual quality — ensuring that every part meets SABEU’s exacting standards. If something’s off, he acts fast to prevent errors before they happen.

The six-eyes principle

“First, my colleagues check the parts. Then we review the results and perform a final inspection — so every part that leaves SABEU meets our highest standards.”

His most important tools:

A magnifying glass, caliper, and depth gauge — the essentials for precision work.